Online DoE with Constraint Modeling (ODCM)

Online DoE with Constraint Modeling can help you with this task:

The input parameters (speed, load, etc.) are varied within the range of interest according to a space-filling design (DoE![]() Design of Experiment). A non-parametric, data-based model (Gaussian Process Model) is built from the acquired data. To avoid interruptions and wasted time at the engine test bench, combinations of input parameters (speed, load, etc.) in which the engine is not drivable (non-feasible) must be excluded from the DoE. On the other hand, the drivable range of the engine must be considered as completely as possible in order to obtain an accurate data-based model even in the peripheral and very interesting range of the engine. Another challenge is the lack of sufficient knowledge about the behavior of the engine at an early stage of development.

Design of Experiment). A non-parametric, data-based model (Gaussian Process Model) is built from the acquired data. To avoid interruptions and wasted time at the engine test bench, combinations of input parameters (speed, load, etc.) in which the engine is not drivable (non-feasible) must be excluded from the DoE. On the other hand, the drivable range of the engine must be considered as completely as possible in order to obtain an accurate data-based model even in the peripheral and very interesting range of the engine. Another challenge is the lack of sufficient knowledge about the behavior of the engine at an early stage of development.

ODCM![]() Online DoE with Constraint Modeling creates a classification model of the boundaries of the drivable region with online updates after each measurement point. Combinations of input parameters in which the engine should not run can be skipped automatically. With this method, less effort is required in the DoE, while the drivable region is covered as completely as possible.

Online DoE with Constraint Modeling creates a classification model of the boundaries of the drivable region with online updates after each measurement point. Combinations of input parameters in which the engine should not run can be skipped automatically. With this method, less effort is required in the DoE, while the drivable region is covered as completely as possible.

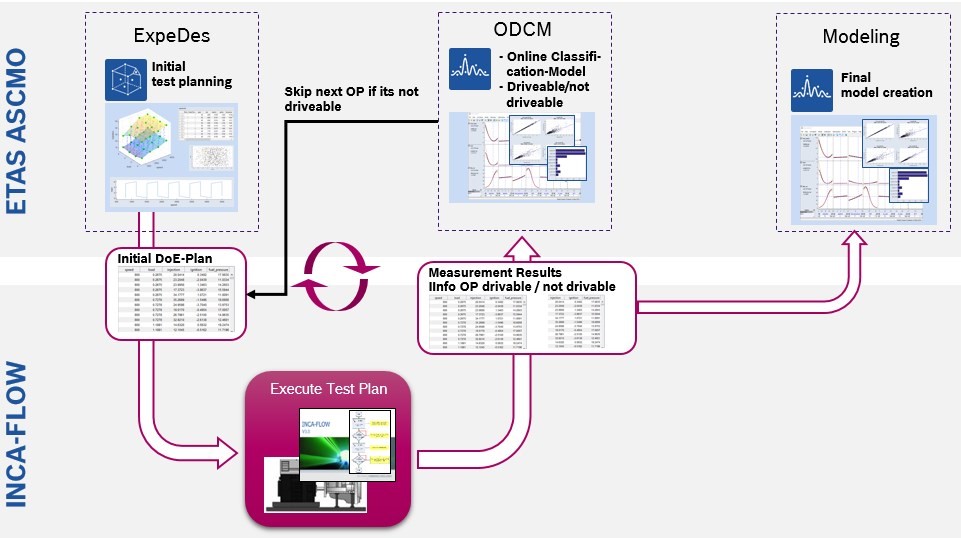

ODCM is used via the ETAS ASCMO API, while "odcmStart" is the entry point. Usually, the ETAS product INCA Flow is used to access the test bench.

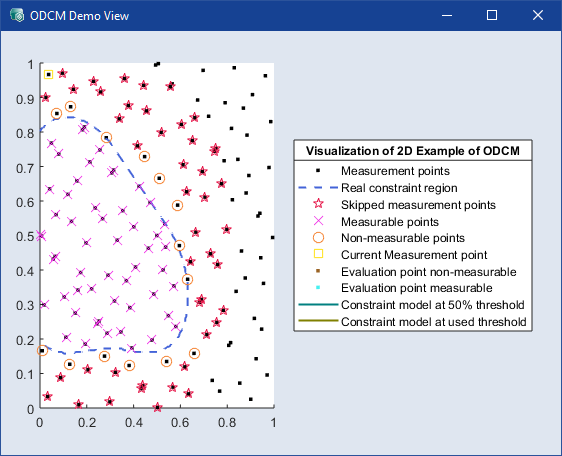

A 2D example showing the real bounded and actually measured and skipped points during a measurement campaign with ODCM:

ASCMO-STATIC ExpeDes has a component Manual ODCM Front End to train the classification model by manually entering the feasible/non-feasible points. It can be started from ASCMO-STATIC ExpeDes > Extra > Open ODCM Front End. For more information see Manual ODCM Front End.

See also